Click on each equipment to implement your maintenance strategy

| Part | Yearly cost per aircraft | Your score |

|---|---|---|

|

Oil filter i

Test

|

$ | |

|

Shock absorber i

Test

|

$ | |

|

Anti-skid valve i

Test

|

$ | |

|

Hydraulic pump i

Test

|

$ |

Aircraft type :

Flights mean duration :

Flights mean quantity per day :

AOG costs :

Interface

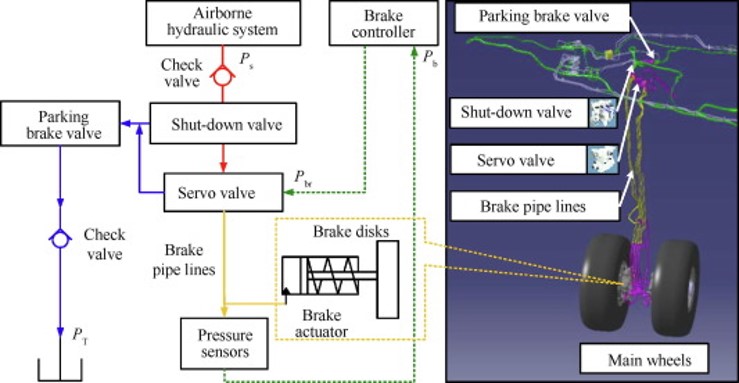

Antiskid braking servo-valve

| Function: | To control brakes |

|---|---|

| Possible causes of failure: | Leakage |

| Mean Time Between Failure: | 7000 flight cycles |

| In case of failure: | NOGO |

Antiskid braking servo-valve

Corrective maintenance

| Mean time to repair | |

|---|---|

| hours | |

| Workman cost | |

| $ | |

| Spare part + logistic cost | |

| $ | |

| Aircraft on ground | |

| Yes |

1/4

Antiskid braking servo-valve

Preventive maintenance

| Mean time to repair |

|---|

| 2 hours |

| Workman cost |

| 800$ |

| Spare part & logistic cost |

| 5 500$ |

| Aircraft on ground |

| No |

|

Periodicity

|

| Every flight cycles |

2/4

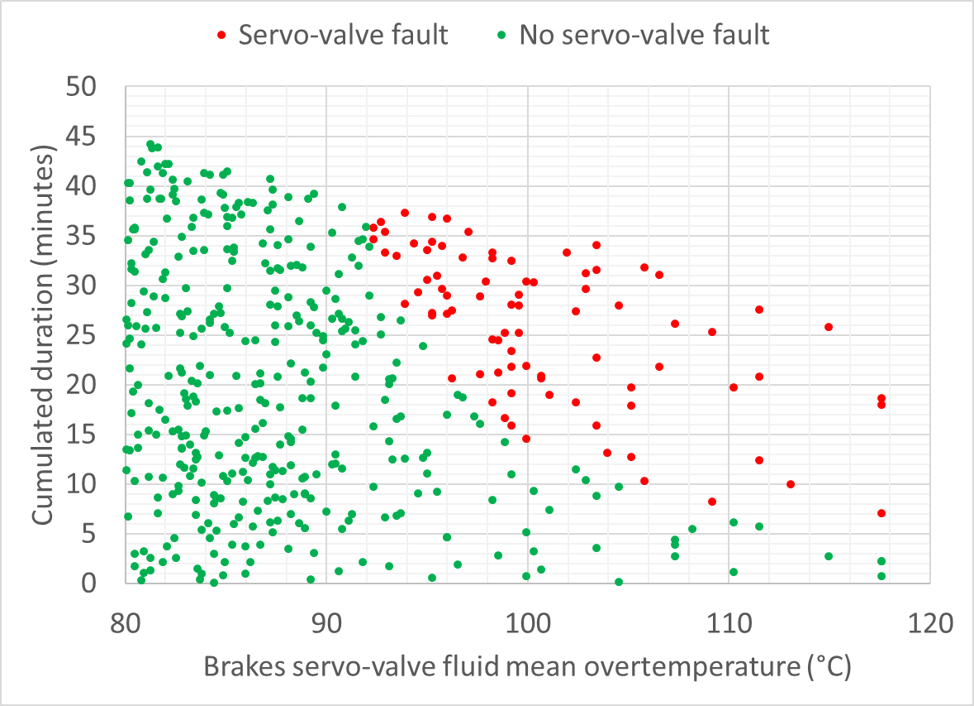

Antiskid braking servo-valve

Predictive maintenance (1/2)

| Mean time to repair |

|---|

| 2 hours |

| Workman cost |

| 800$ |

| Spare part + logistic cost |

| 5 500$ |

| Aircraft on ground |

| No |

3/4

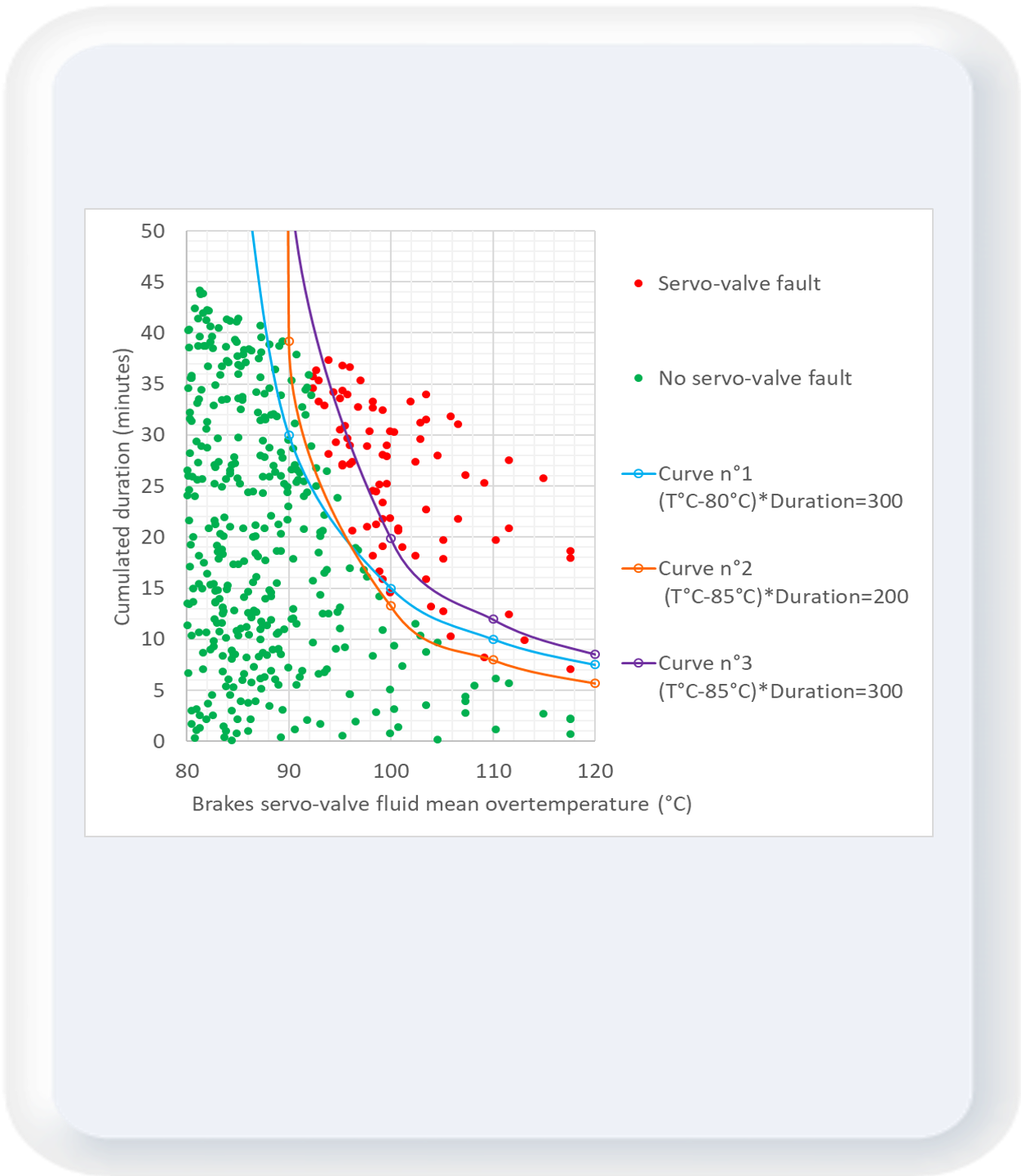

Antiskid braking servo-valve

Predictive maintenance (2/2)

| Invest in predictive system If yes yearly cost is : 1 000 $ per AC |

|---|

|

|

| Objective |

| Predict a failure 10 flights (minimum) in advance |

| Parameter to monitor |

|

T = Fluid temperature (C°) D = Cumulated duration at high temperature (minutes) |

| Algorithm |

|

Threshold on Cumulated duration at high temperature (T-

Tlimit)*D > Dlimit Limit-Curve n° |

4/4

Close

The servo-valve controls the flow of hydraulic fluid which

pressure to the brake pads to slow down the aircraft. When the

brakes are applied, the resulting friction generates heat, which

can cause the temperature of the hydraulic fluid to rise. If the

temperature of the hydraulic fluid gets too high, it can cause

the seals and other components in the servo-valve to wear more

quickly, which can lead to reduced performance and eventually

failure of the valve. The normal operating temperature of the

hydraulic fluid in the brake system is between 100°F to 180°F

(38°C to 82°C).

Oil filter

| Function: | To filter contaminants from engine oil |

|---|---|

| Possible causes of failure: | Filter clogging |

| Mean Time Between Failure: | 200 flight hours |

| In case of failure: | NOGO |

Oil filter

Corrective maintenance

| Mean time to repair | |

|---|---|

| hours | |

| Workman cost | |

| $ | |

| Spare part + logistic cost | |

| $ | |

| Aircraft on ground | |

| Yes |

1/4

Oil filter

Preventive maintenance

| Mean time to repair |

|---|

| 1 hour |

| Workman cost |

| 200$ |

| Spare part + logistic cost |

| 210$ |

| Aircraft on ground |

| No |

|

Periodicity

|

| Every flight hours |

2/4

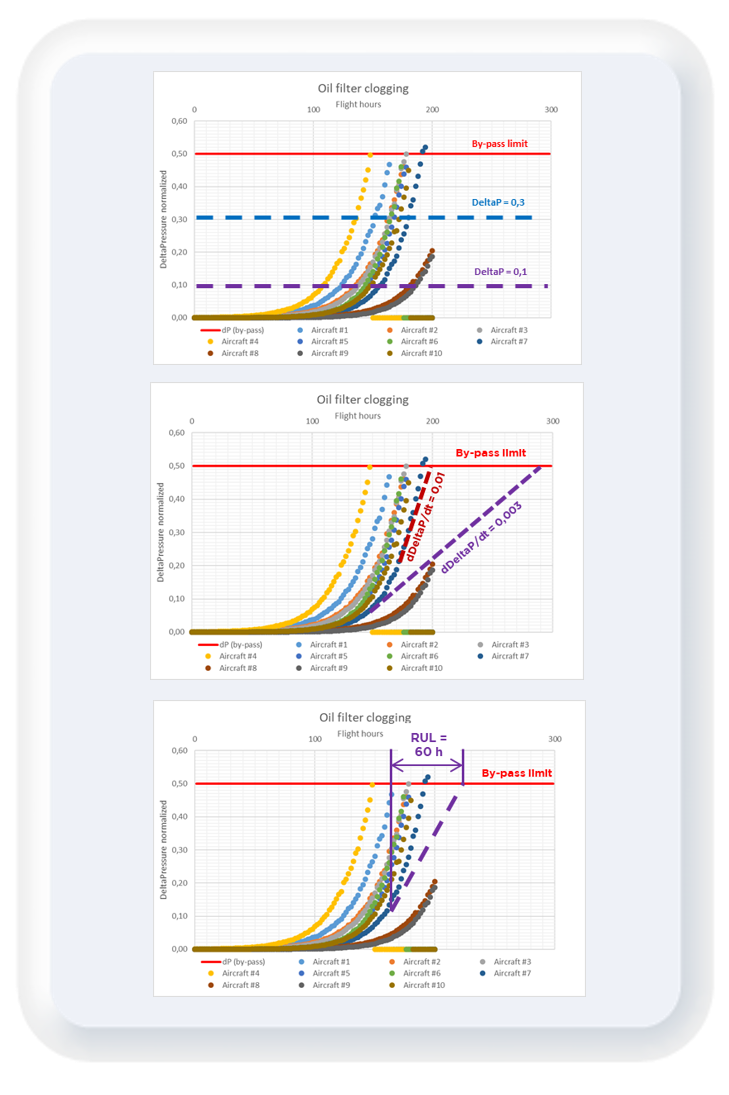

Oil filter

Predictive maintenance (1/2)

| Mean time to repair |

|---|

| 1 hour |

| Workman cost |

| 200$ |

| Spare part + logistic cost |

| 210$ |

| Aircraft on ground |

| No |

3/4

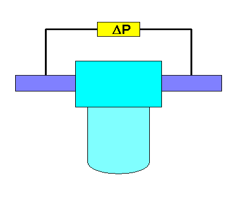

Oil filter

Predictive maintenance (2/2)

| Invest in predictive system if yes, cost is 500$ per AC |

|---|

|

|

| Objective |

| Predict a failure 10 flights (minimum) in advance |

| Parameter to monitor |

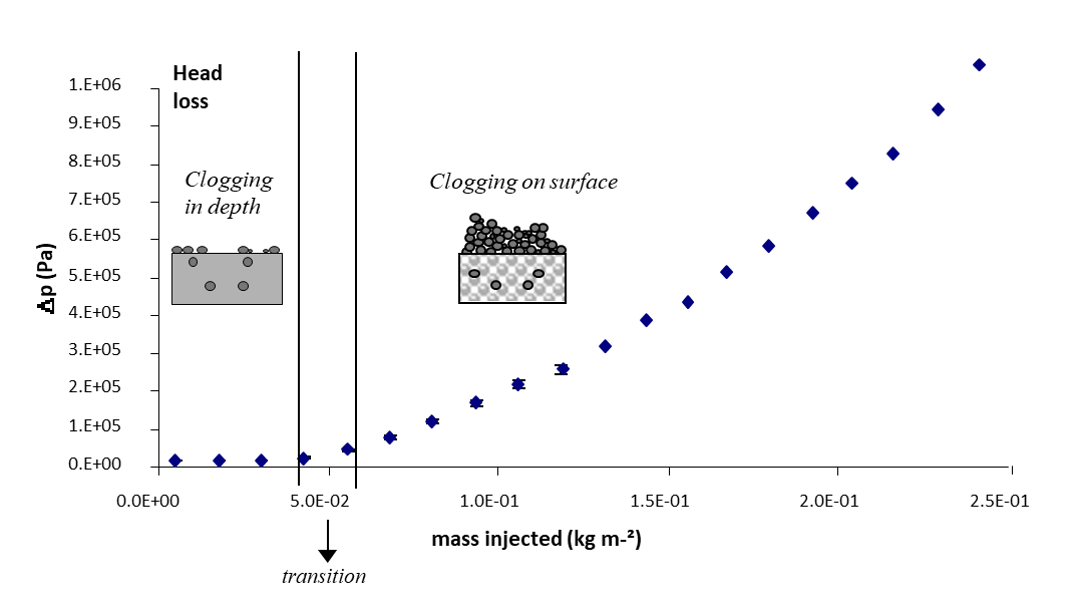

| DeltaP : delta Pressure (normalized) |

| Algorithm |

4/4

Close

Filter clogging proceed in two steps:

1. Clogging in depth

2. Clogging on surface

When clogging on surface occurs, the delta pressure increases quickly with operating time and can reach a value for which oil-filter by-pass is activated.

1. Clogging in depth

2. Clogging on surface

When clogging on surface occurs, the delta pressure increases quickly with operating time and can reach a value for which oil-filter by-pass is activated.

Hydraulic pump

| Function: | To maintain appropriate hydraulic pressure |

|---|---|

| Possible causes of failure: |

|

| Mean Time Between Failure: | 20 000 flight hours |

| In case of failure: | NOGO |

Hydraulic pump

Corrective maintenance

| Mean time to repair | |

|---|---|

| hours | |

| Workman cost | |

| $ | |

| Spare part + logistic cost | |

| $ | |

| Aircraft on ground | |

| Yes |

1/4

Hydraulic pump

Preventive maintenance

| Mean time to repair |

|---|

| 2 hours |

| Workman cost |

| 800$ |

| Spare part + logistic cost |

| 8 500$ |

| Aircraft on ground |

| No |

|

Periodicity

|

| Every flight hours |

2/4

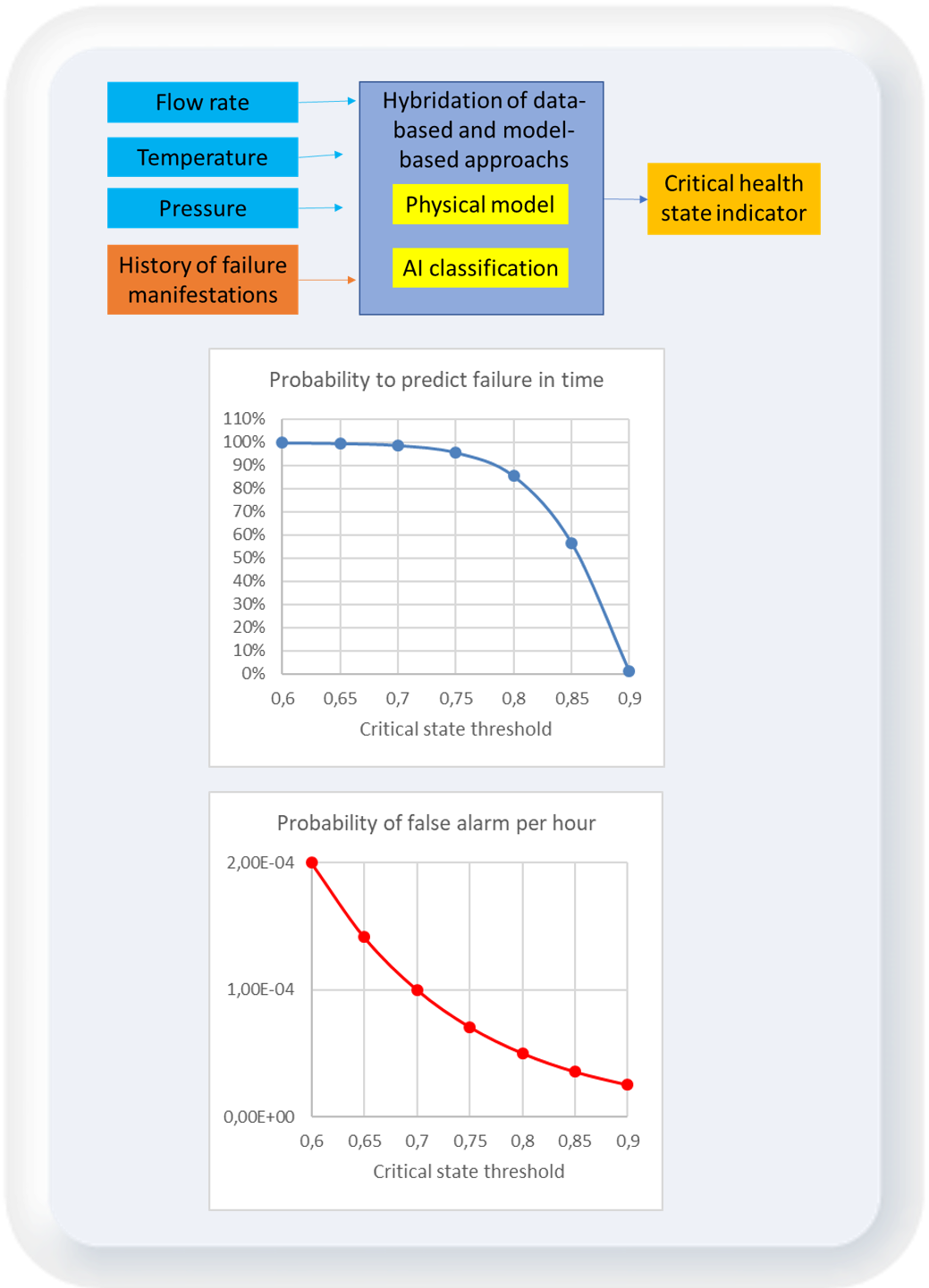

Hydraulic pump

Predictive maintenance (1/2)

| Mean time to repair |

|---|

| 2 hours |

| Workman cost |

| 800$ |

| Spare part + logistic cost |

| 8 500$ |

| Aircraft on ground |

| No |

3/4

Hydraulic pump

Predictive maintenance (2/2)

| Invest in predictive system if yes, yearly cost is 1 000$ per AC |

|---|

|

|

| Objective |

| Predict a failure 10 flights (minimum) in advance |

| Parameter to monitor |

|

Critical health state indicator calculated by an algorithm

based on : Flow rate, pressure and temperature measurements Hybridation with a physical model of the pump AI classification trained on failure manifestations |

| Algorithm |

4/4

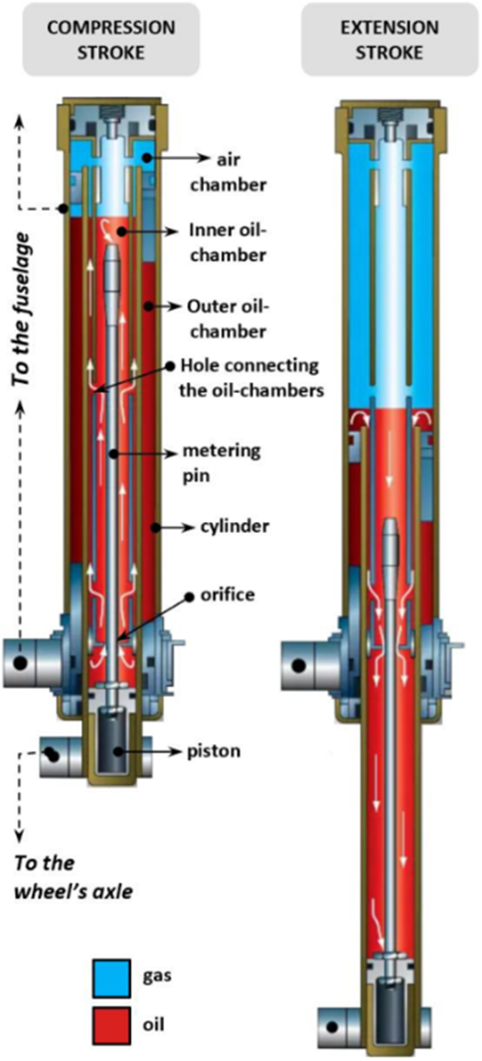

Landing gear shock-absorber

| Function: | Reduce the impact force at landing |

|---|---|

| Possible causes of failure: |

|

| Mean Time Between Failure: | 10 000 flight cycles |

| In case of failure : | NOGO |

Landing gear shock-absorber

Corrective maintenance

| Mean time to repair | |

|---|---|

| hours | |

| Workman cost | |

| $ | |

| Spare part + logistic cost | |

| $ | |

| Aircraft on ground | |

| Yes |

1/4

Landing gear shock-absorber

Preventive maintenance

| Mean time to repair |

|---|

| 6 hours |

| Workman cost |

| 4 800$ |

| Spare part + logistic cost |

| 5 500$ |

| Aircraft on ground |

| No |

|

Periodicity

|

| Every flight cycles |

2/4

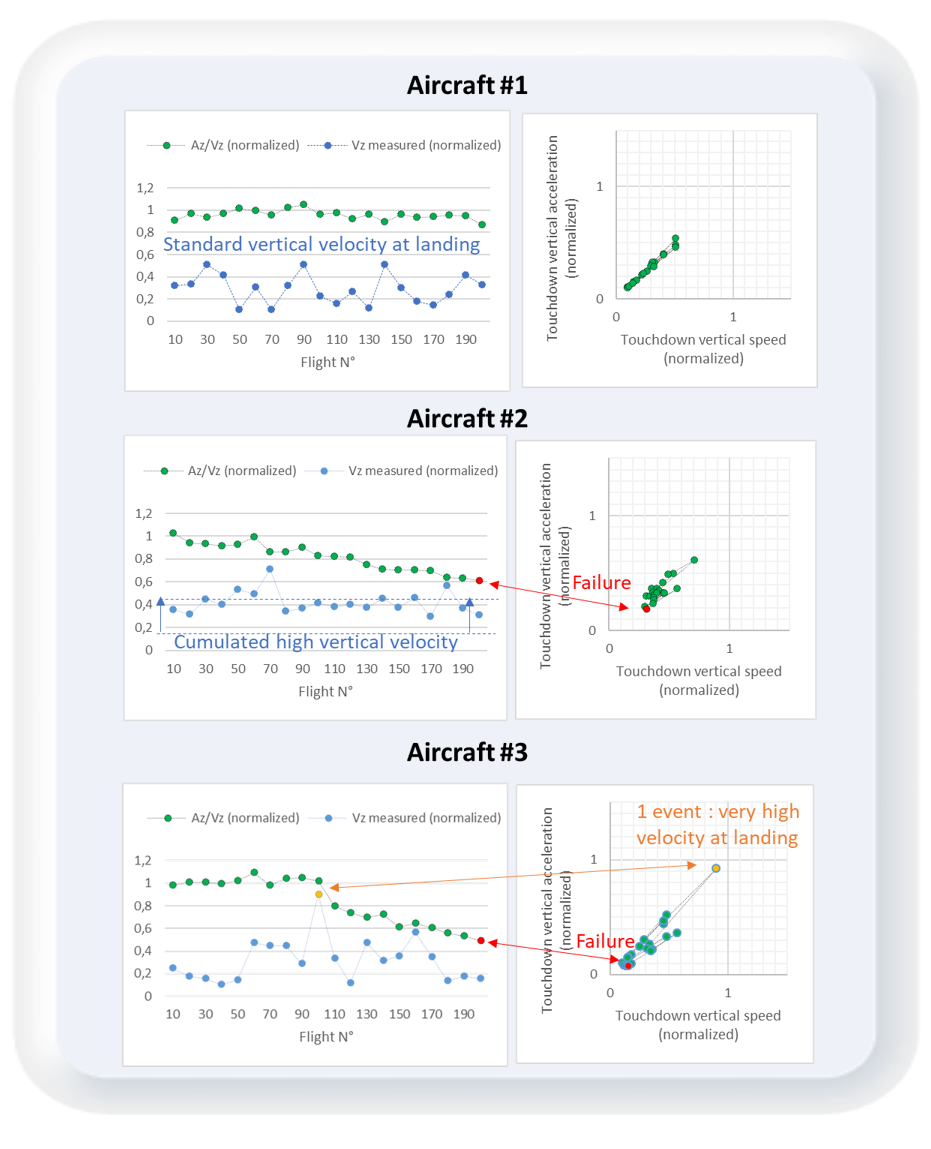

Landing gear shock-absorber

Predictive maintenance (1/2)

| Mean time to repair |

|---|

| 6 hours |

| Workman cost |

| 4 800$ |

| Spare part + logistic cost |

| 5 500$ |

| Aircraft on ground |

| No |

3/4

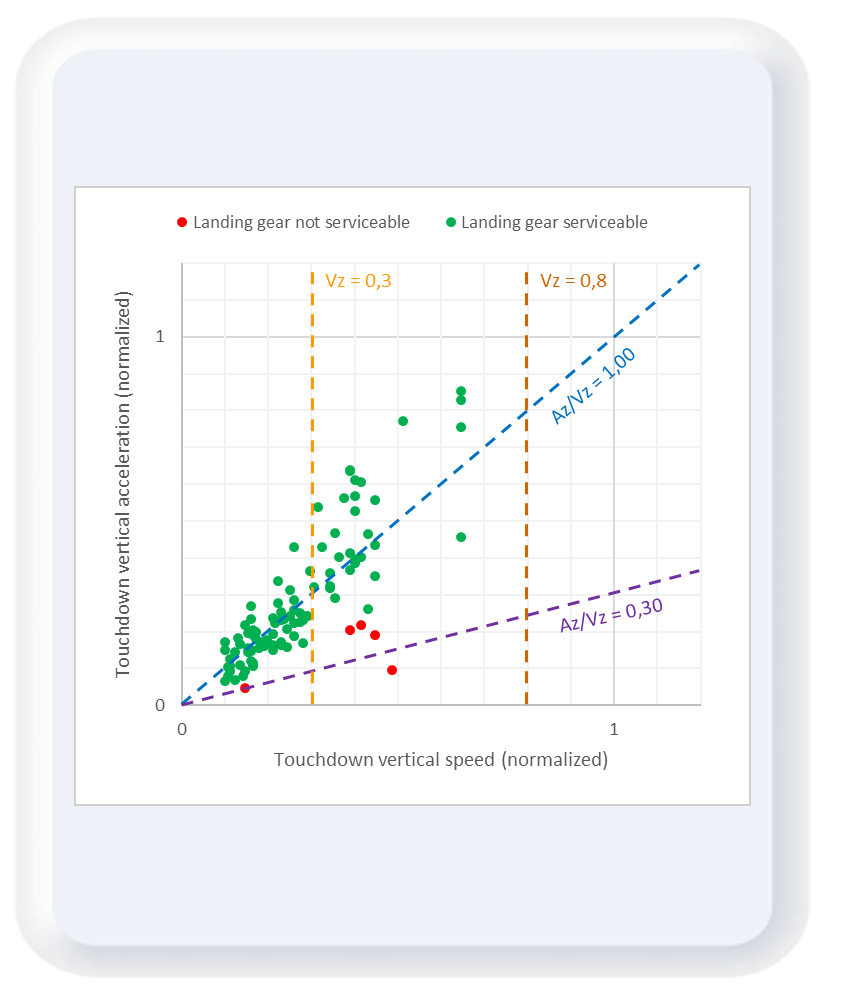

Landing gear shock-absorber

Predictive maintenance (2/2)

| Invest in predictive system if yes, yearly cost is 1 000$ per AC |

|---|

|

|

| Objective |

| Predict a failure 10 flights (minimum) in advance |

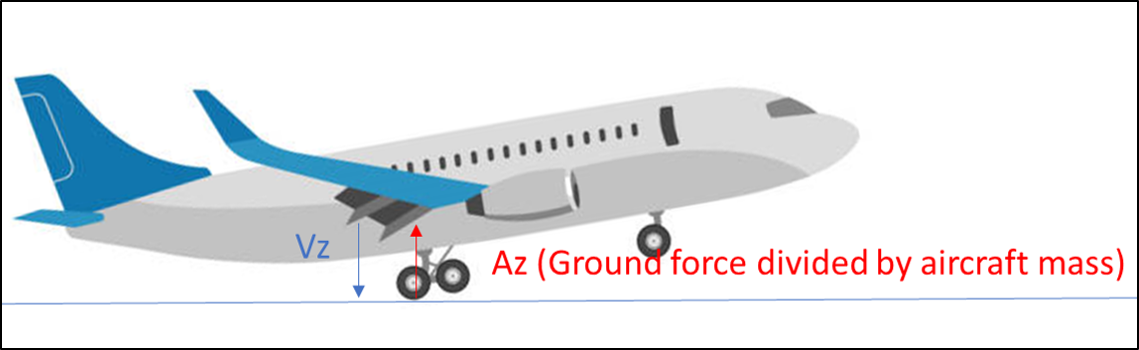

| Parameter to monitor |

|

Vz : Vertical velocity (at touchdown) - normalized Az : Vertical acceleration (at touchdown) - normalized |

| Algorithm |

4/4

Close

Landing gear shock absorber pressurizes air or oil to absorb

shock. Oleo strut features a cylinder. Within this cylinder is

air or oil. Upon touching down on a runway, the landing force

will move a piston into this cylinder, thus pressurizing the

contained air or oil. At landing, high vertical velocity(Vz)

can damage the shock absorber. The shock at landing can be

estimated by measuring vertical acceleration (Az) and taking

into account the aircraft mass.

Close